Toray’s TORAYCA™ carbon fiber is globally recognized for its outstanding performance, quality, and consistency in processing.

TORAYCA™ carbon fiber is known worldwide for its exceptional quality, reliability, and versatility. Whether you’re in aerospace, industrial manufacturing, or recreational industries, these fibers deliver outstanding performance tailored to your needs.

A History of Innovation

Toray has been a leader in carbon fiber manufacturing since 1971, becoming the first company to commercially produce polyacrylonitrile (PAN)-based carbon fibers. In the U.S., production began in Decatur, Alabama, in 1999 and has recently expanded to Spartanburg, South Carolina, to better serve a growing market.

Global Leadership in Carbon Fiber

As the largest carbon fiber producer in the world, Toray manufactures 29,100 metric tons annually, with facilities in the U.S., Japan, France, and South Korea. Wherever you are, Toray’s global presence ensures quality and consistency.

A Range of Products for Every Need

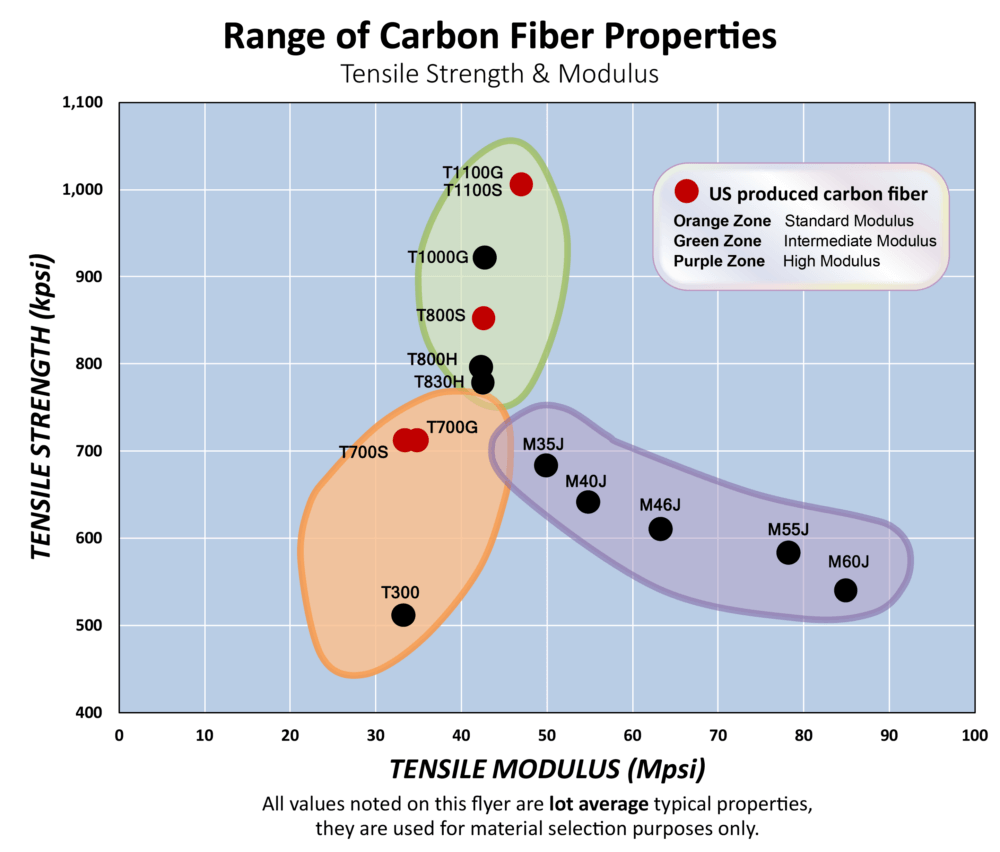

Standard-Modulus Fibers: Affordable and perfect for general-purpose applications.

Intermediate-Modulus Fibers: Great for projects requiring extra stiffness and strength.

High-Modulus Fibers: The ultimate choice for high-performance applications like aerospace and advanced industrial use.

Benefits Choose TORAYCA™.

Versatility: Originally developed for aerospace, TORAYCA™ fibers are now used in a wide variety of industries, from industrial equipment to sports and recreation.

Proven Quality: With decades of experience, Toray ensures every product delivers consistent, top-tier performance.

Tailored Solutions: A broad selection of fibers is available to meet your unique application requirements.

With TORAYCA™ carbon fibers, you get more than just materials—you get trusted solutions backed by innovation and expertise.

Download our Carbon Fiber Selector Guide

50 years with Toray

We’re excited for the next 50 years, as we build on our rich history and focus on enabling technology, processability, efficiency, and high-rate manufacturing for our customers.

Types of Carbon Fiber

A comprehensive TORAYCA™ Technical Manual is available with further information that may assist you in selecting the correct carbon fiber product for your specific application some of these include T1100 carbon fiber, High modulus carbon fiber, and intermediate modulus carbon fiber.

The tables below show the TORAYCA™ carbon fiber product line available along with some of their properties and a link to the technical datasheet.

Standard Modulus Carbon Fibers

-

About Standard Modulus

-

Standard modulus carbon fibers typically exhibit a fiber modulus of 33-34 Msi or slightly higher. These are the most cost-effective fibers as measured by tensile strength or modulus per unit cost. Toray’s T300 standard modulus carbon fibers are a recognized industry standard, having been in production since 1971. T700S is a high tensile strength, standard modulus carbon fiber which is another standard industrial fiber. Standard modulus carbon fibers are available in tow sizes from 1K to 24K.

- T300 – Baseline carbon fiber used in aerospace applications with over 20-year service history. Has 30-year production history and is known for balanced composite properties, high quality and consistency, reliability and availability of supply. Available in 1K, 3K, 6K and 12K tow sizes.

- T700S – An industry standard fiber for high strength and standard modulus, with outstanding processing characteristics for filament winding, weaving and prepregging. This never-twisted fiber is used in a variety of industrial and recreational applications, including pressure vessels such as natural gas vehicle (NGV) storage tanks and SCBA breathing tanks. Available in 6K, 12K, and 24K tow sizes.

- T700G – Enhanced tensile modulus and adhesion properties over T700S. Applications of this never-twisted fiber include aircraft and high-performance sporting goods where demanding conditions require superior composite properties. Available in 12K tow sizes.

| Fiber Type | Tensile Strength* (ksi) | Tensile Strength* (MPa) | Tensile Modulus* (MSi) | Tensile Modulus* (GPa) | Common Applications | Datasheet [PDF] |

|---|---|---|---|---|---|---|

| T300 | 512 | 3,530 | 33.4 | 230 | Various including weaving and prepreg, especially for drapability | T300 Datasheet |

| T700S | 711 | 4,900 | 33.4 | 230 | Various including filament winding and pultrusion | T700S Datasheet |

| T700G | 711 | 4,900 | 34.8 | 240 | Various including weaving and prepreg with enhanced fiber/resin adhesion | T700G Datasheet |

Intermediate Modulus Carbon Fibers

-

About Intermediate Modulus

-

Intermediate modulus (IM) carbon fibers exhibit a tensile modulus of 42 Msi. Originally developed for aerospace applications, IM fibers now find use in recreational and industrial applications as well. Toray offers a broad range of IM fibers with a mix of price and performance characteristics to meet the needs in a broad range of industries. Toray’s IM fibers are available in 6K, 12K, and 24K tow sizes.

- T800H – An intermediate modulus, high tensile strength fiber, with high level and balance composite properties. Designed and developed to meet the weight saving demands of aircraft applications. Is used in primary structure of commercial aircraft, including vertical fin and horizontal stabilizers. Available in 6K and 12K tow sizes.

- T800S – A cost-effective intermediate modulus fiber with higher tensile strength compared to T800H. This never-twisted fiber has especially high tensile properties. Is used extensively in primary structure of commercial aircraft. Available in 12K and 24K tow sizes.

- T1000G – A high tensile strength carbon fiber. Suitable for lightweight, tensile strength critical applications such as pressure vessels for aerospace vehicles, and satellites, as well as hydrogen storage tanks for fuel cell vehicles. Available only in a 12K tow size.

- T1100G – Next-generation intermediate modulus fiber with excellent processability in high-performance manufacturing methods such as weaving, prepreg, etc. Available in 12K and 24K tow sizes.

- T1100S – Next-generation intermediate modulus fiber with excellent processability and enhanced performance in demanding manufacturing methods such as filament winding. Available in 12K and 24K tow sizes.

| Fiber Type | Tensile Strength* (ksi) | Tensile Strength* (MPa) | Tensile Modulus* (MSi) | Tensile Modulus* (GPa) | Common Applications | Datasheet |

|---|---|---|---|---|---|---|

| T800H | 796 | 5,490 | 42.7 | 294 | Weaving and prepreg | T800H Datasheet |

| T800S | 853 | 5,880 | 42.7 | 294 | Various including prepreg unidirectional tape | T800S Datasheet |

| T1000G | 924 | 6,370 | 42.7 | 294 | Filament winding | T1000G Datasheet |

| T1100S | 1,017 | 7,000 | 47.0 | 324 | Various including filament winding | T1100S Datasheet |

| T1100G | 1,017 | 7,000 | 47.0 | 324 | Various including weaving and prepreg | T1100G Datasheet |

High Modulus Carbon Fibers

-

About High Modulus

-

Toray’s MJ and M-series high modulus carbon fibers represent the highest modulus PAN-based carbon fibers available. PAN-based high modulus fibers are superior to pitch-based fibers due to tensile and compressive strengths that are often times more than twice that of a corresponding pitch-based fiber. The MJ series fibers offer enhanced tensile strength and elongation over M series fibers. They are typically used in stiffness and coefficient of thermal expansion (CTE)-critical applications such as spacecraft, premium sporting goods and industrial rollers.

| Fiber Type | Tensile Strength* (ksi) | Tensile Strength* (MPa) | Tensile Modulus* (MSi) | Tensile Modulus* (GPa) | Common Applications | Datasheet |

|---|---|---|---|---|---|---|

| M35J | 654(6K) | 683(12K) | 4,510(6K) | 4,700(12K) | 49.8 | 343 | Various including weaving and specialty prepreg | M35J Datasheet |

| M40J | 640 | 4,400 | 54.7 | 377 | Various including weaving and specialty prepreg | M40J Datasheet |

| M46J | 609(6K) | 583(12K) | 4,200(6K) | 4,020(12K) | 63.3 | 436 | Various including weaving and specialty prepreg | M46J Datasheet |

| M55J | 583 | 4,020 | 78.2 | 540 | Various including weaving and specialty prepreg | M55J Datasheet |

| M60J | 554 | 3,820 | 85.3 | 588 | Various including weaving and specialty prepreg | M60J Datasheet |

Industries

Important features of TORAYCA™ carbon fiber products include:

- The broadest product line available, including the highest strength and stiffness fibers available in the marketplace.

- Minimal deformation due to thermal effects, with coefficients of thermal expansion in the axis direction on the order of -0.4 to -1.0 x10-6/K.

- Electrical conductivity and transparency to X-ray radiation.

- Acid, alkali, salt and solvent resistance.

- A selection of surface characteristics for compatibility with high-performance epoxy resin systems as well as phenolic, vinyl ester and unsaturated polyester resin systems.

- Versatility to be processed using a variety of composite processing methods including weaving, braiding, prepregging, filament winding, pultrusion, chopping and milling.

- Manufacturing under ISO 9001 quality assurance systems, with identical product manufacturing specifications, regardless of the location of manufacture.